Rigid Heddle Weaving

Marcy Petrini

January 2019

I love plain weave, especially weaving it off with variegated, textured yarns, and I like to experiment with the color interactions. I can weave it on my floor loom, so investing in a rigid heddle loom didn’t seem to make sense, especially since I had bought one in the late 80s which for me turned out to be slower to dress than my floor loom.

I love plain weave, especially weaving it off with variegated, textured yarns, and I like to experiment with the color interactions. I can weave it on my floor loom, so investing in a rigid heddle loom didn’t seem to make sense, especially since I had bought one in the late 80s which for me turned out to be slower to dress than my floor loom.

But when I saw how quickly my friend and colleague Kathy Perito dressed her Schacht Cricket, I started to think that it would great to weave by the fire in the evenings, with a glass of wine and a cat or two, chatting with my husband. After talking with Kathy, this is what I asked Santa Clause:

- A Schacht Flip loom because it can be expanded to two heddles (in case I get ambitious) and it can also be folded

- A stand so I wouldn’t need a table, and I could transport the loom anywhere.

- A heddle of 12 dents/inch, for now, because I don’t have much yarn that I would sett more openly; with the Flip loom there is a choice of heddle sett.

The loom arrived and in less than 2 hours, it was assembled, placed on its stand, dressed, threaded and ready to weave! I must admit that a lot of the assembling was done by my husband Terry who has a tendency to take over (maybe because he knows I can be a klutz).

I chose a bright green 3/2 cotton, which is perfect sett at 12 epi for plain weave. For weft, I found in my stash a fat textured, multicolored chenille yarn with a binder of black hair yarn around the chenille; the yarn, Trendsetter Yarns Savvy, wraps at 5 wpi, shown below.

With a yarn that thick normally we would sett the warp more openly to accommodate the weft, but since this yarn is basically chenille, opening the sett wasn’t necessary. The conventional wisdom is to treat the chenille as if the fuzzy hair isn’t there, using the core as a guide. I have successfully sett chenille warps closely and I have knitted chenille with much smaller needles than the yarn size would seem to need, as it was recommended to me many years ago.

My sampler scarf was 6” wide with a warp two yards long; it took two hours to complete, including hemming on the loom at the start and at the end with the warp thread. The scarf was light and drapey, despite the fat weft and the dense warp.

I washed the scarf on my front loader machine on the “hand wash” cycle which I use for all of my handwoven scarves and shawls, including silk, even though the directions for the weft yarn say that dry cleaning is recommended. Coming off the washer, I didn’t notice any problems, but the scarf was very wet; since the weft is 62% acrylic and 38% polyester, I saw no harm in drying it in the dryer at very low heat.

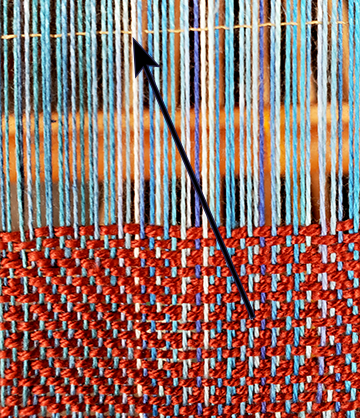

The harm was in the disaster that ensued! Warp ends bunched and the weft inch wormed, as shown below:

Every mistake is an opportunity to learn. I didn’t think that the warp bunching was the result of the sett; I hypothesized that I didn’t beat the weft enough; the warp, then, had lots of wiggle room which was accelerated while tumbling in the drier. I think that if I hadn’t tumble-dried it, the bunching and inch-worming would have occurred with use – I have had that happen before.

Looking back at it, I did find it hard to beat with the rigid heddle, but since my natural beat is pretty hard, I didn’t think that the light beat was necessarily a bad thing. The weft beat is always related to the warp tension and, as I read and as confirmed by Kathy, it’s harder to keep a firm tension on a light-weight, portable rigid heddle loom than on a solid floor loom. On my floor looms, I adjust the warp tension according to the beat I want the fabric to have, but on the rigid heddle loom there isn’t much wiggle room.

But how do you translate the adjustment to make on the beat, given a soft tension on a light loom? Experience!

To prove my hypothesis that it was the beat that caused the problem, I put a new warp on the Flip loom, with the same yarn and woven with the same weft; this time I beat it with a tapestry beater. The fabric is a lot denser and not as drapable, but there is no inch-worming and minimal warp bunching after washing the same way.

For a true experiment, I should have dried it in the drier, but I was afraid that the fabric would become denser still. But it is pretty convincing that the beat was the culprit.

So, on warp #3, I am practicing my beat, trying to keep it even by measuring the ppi often. There will be a follow up report!

Happy weaving!

Please email comments and questions to

Lacey Stripes

Marcy Petrini

December, 2018

I was thinking of possible interesting structures that I may add to the Pictionary, when I remembered a fabric I wove a long time ago, so long that I actually wove it with crochet cotton because there were no yarn shops in town and my mail order yarn was back ordered.

Unfortunately, I don’t remember where I learned this, but my notes say that it was a combination structure, combining a pointed twill with plain weave. Looking at it now, I think I would classify it as a treadling method because the resulting fabric produces lacey stripes and stripes of plain weave.

Unlike classical woven laces, where each block can generally weave either floats or plain weave, in this structure each area can only weave plain weave or the lacey stripe. Furthermore, to show case the lacey stripes better, the sleying is specific.

As shown in the drawdown below, the plain weave is threaded 2, 3, shown in brown, and repeated as long as we wish. The lacey stripes, shown in red, are made up of two units: 2, 1, 2 (A) and 3, 4, 3 (B); the two alternates for as many repeats as desired, with a balancing A unit at the end of the repeat; the following plain weave, then, starts on shaft 3. In the lacey units there are both warp and weft floats.

Click here for the full-sized draft (a PDF will open a new window)

Sleying is easiest if the denting of the reed is the same as the tabby sett for the warp yarn; then the stripe threaded 2, 3 is sleyed 1 per dent. The sleying for the lacey units is:

- 2, 1, 2 in one dent

- Skip 2 dents

- 3, 4, 3 in one dent

- Skip 2 dents.

From the drawdown we see that the treadling only requires 4 treadles since there are two shots on 1 & 3 for each repeat; similarly, there are two shots for 4 & 2; using the 6 treadles usually available with a 4-shaft loom makes the treadling easier and more efficient.

After wet finishing, the lacey stripes are more obvious as can be seen by the picture of the cloth, while the drawdown shows the actual structure of the fabric.

Next time you want to weave lace, try stripes! A Pictionary entry (click here) has been added for this structure.

Happy weaving!

Please email comments and questions to

This blog has been clarified since the initial posting. Thank you to Kathy Perito to bring the inconsistencies to my attention.

Twill Blocks on Four Shafts

Marcy Petrini

November, 2018

When we think of twill blocks, we generally don’t mean on four shafts, but I was intrigued by the “Twill Blocks No. 2” in Marguerite Porter Davison’s book A Handweaver’s Pattern Book (page 31 of 1994 revised edition – but I don’t see a No. 1!), so I decided I would weave a scarf using treadling II.

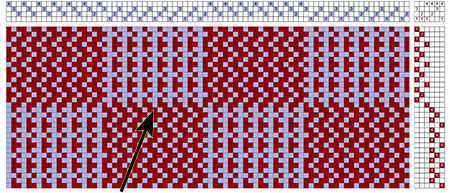

I always do a drawdown for my projects and good thing I did! Using the exact directions in the book, my drawdown looks like this:

Click here for the full-sized draft (a PDF will open a new window)

At first I thought I had made a mistake, but, no, the error wasn’t mine. Length-wise warp floats appear in one block from shaft 1 always being raised, and on shaft 4 in the other block. In order to weave it, I would have to modify the tie-up to avoid the long warp floats.

The solution is to remove shaft 1 from one of the treadles for the 1st block and, similarly, remove shaft 4 from one of the treadles for the 2nd block.

I chose to detach the appropriate shaft from the 2nd treadle of each block. Here is the drawdown I used, but the solution is not unique, other combinations could be used.

Click here for the full-sized draft (a PDF will open a new window)

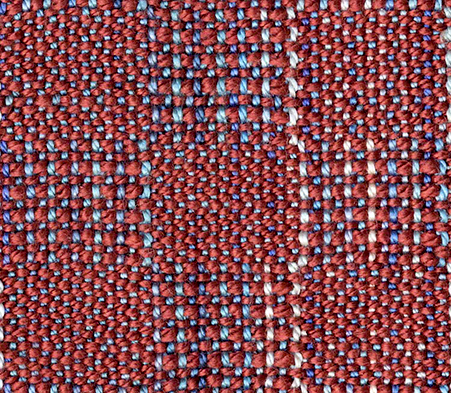

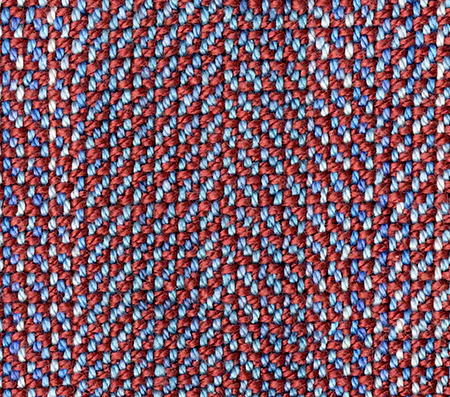

And here is a close-up of the fabric.

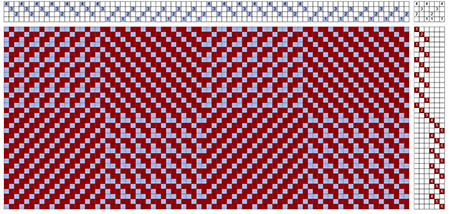

For another possibility, I thought it may be fun to have the blocks alternate a 2/1 straight twill; here is the drawdown. With 6 treadles, this is easier to weave.

Click here for the full-sized draft (a PDF will open a new window)

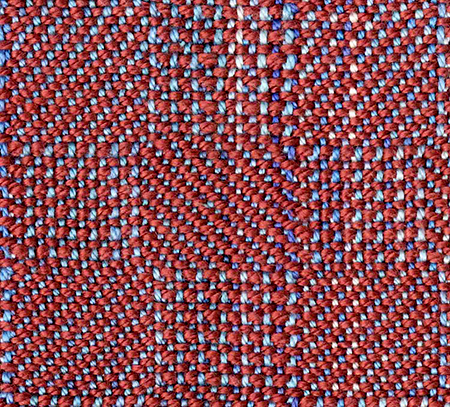

And here is a close-up of the fabric.

These blocks are so subtle that they are difficult to see while weaving, so I used the old lace knitting trick, the lifeline, and placed a sewing thread in the same shed as the first shot of the block.

Starting from the sewing thread, I could then easily count how many shots I had woven for the given block; at the end of the block, I removed the sewing thread and placed it at the beginning of the next block.

I used a strand of sewing thread long on both sides of the weaving edges to give me mechanical advantage in pulling it out after the weaving; to avoid the long thread getting in the way, I temporarily tacked it down with blue painter’s tape.

I used one set of blocks on each end of the scarf, but for the middle, I wanted the design to be more flowing, so I wove it with a straight draw which results in stripes of right-hand and left-hand broken twill lines. Here is the drawdown:

Click here for the full-sized draft (a PDF will open a new window)

And a close up of the fabric.

If you have never woven twill blocks on 4 shafts, give them a try!

Happy weaving!

Please email comments and questions to

Piqué in the Pictionary

Marcy Petrini

October, 2018

I learned about piqué from a workshop by Donna Sullivan who had just written her book, Pique: Plain and Patterned. While some fancy fabrics require more shafts, on four it is possible to weave plain piqué, also called ribbed, with either a loose-back or a fast-back.

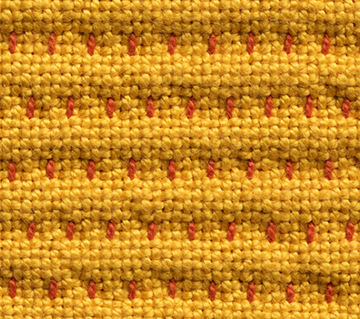

The Pictionary now has a piqué page, but here is some of the information. There are two warps; the first forms a balanced cloth by interlacing with a weft of the same size; they are called the face warp and weft, in the picture below in yellow.

The orange warp is a stitcher warp, tensioned separately and tightly, which causes the characteristic puckering of the fabric. The ridges are made more prominent by using a stuffer weft, the beige fluffy wool, only visible in the back of the fabric shown below.

With two warps and two wefts, the piqué is called loose-back – because it is! In the fabric above, however, there is an additional weft, orange, which interlaces with the stitcher warp, making the fabric a fast-back piqué; even the fast-back is not totally stable, but it would be suitable for any fabric whose back is not exposed, a pillow, or a lined jacket.

In summary: ribbed or plain piqué has always two warps, face and stitcher; the loose-back has two wefts, the face and stuffer; the fast-back has three wefts: face, stuffer, and the stabilizing weft interlacing the stitcher warp.

Pictionary Update

- All of the Convergence® entries are in the Pictionary now, in addition to the few added since:

- piqué in October,

- canvas and (corrected) crepe in September,

- crepe twill in August,

- ribbed twill in July.

- More will be added with time, including shadow weave.

- Meanwhile, here is a quick test whose answers are in the Pictionary:

- Is tabby another name for plain weave?

- What is a fancy twill?

- Do I need to rethread my overshot to change from star to rose fashion?

- What’s the difference between “paired x’s” and “paired o’s” in summer and winter?

- Can I weave waffle weave on four shafts?

Enjoy!

and

Happy weaving!

Please email comments and questions to

Canvas and Crepe

Marcy Petrini

September, 2018

A long time ago, in a galaxy far, far away, in some workshop, I picked up the mistaken notion that canvas weave and crepe weave are related, or maybe even similar. Surprisingly and embarrassingly, I never checked that fact and I kept on weaving crepe weave, calling it canvas and even teaching it.

Recently, when I found a crepe twill, I started wondering what made it a crepe twill. That’s when I finally figure it all out, including why my mistaken notion probably started.

A crepe weave is a treadling method that aims to produce a crepe fabric, which is generally obtained from highly twisted crepe yarns. What makes the cloth from this structure behave similarly to a crepe fabric is the alternating plain weave shots with picks of floats.

The drawdown below shows the “on opposite” tie-up: the pick of 1 & 2 is followed by its opposite 3 & 4, forming two-thread floats; those are followed by the plain weave shots, 2 & 4 vs. 1 & 3, which are also “on opposite: the second pick uses the shafts not used by the first.

Click here for the full-sized draft (a PDF will open a new window)

The fabric shows the characteristic ridges formed by alternating the two on-opposite combinations of treadling.

Below is the drawdown for a crepe twill from Davison’s book. It doesn’t seem to have much in common with the crepe weave, except that it does form 2- and 3-thread floats that may cause the fabric to behave like a crepe cloth.

Click here for the full-sized draft (a PDF will open a new window)

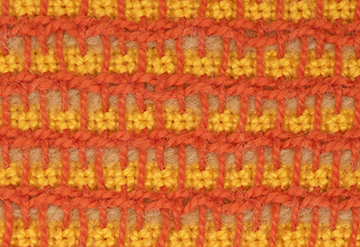

The threading is unusual and the tie-up and treadling are that of a straight draw. The fabric is below.

Compared to the crepe weave fabric, that of the crepe twill seemed to be turned on its side: what if I turned the draft?

Below is the crepe twill turned draft: a straight draw threading, just like the crepe weave; the same “on opposite” tie-up; and a treadling of pointed and reverse pointed twills, which makes it a more obvious twill than the original drawdown.

Click here for the full-sized draft (a PDF will open a new window)

Below is the drawdown of a canvas weave, with the fabric following.

Click here for the full-sized draft (a PDF will open a new window)

The threading and treadling are very distinctive, forming blocks and placing canvas weave in the grouped weave category. But the tie-up is on opposite!

So, a long time ago, in a galaxy far, far away, someone must have told me that the on opposite tie-up is shared by canvas weave and crepe weave (and other structures as well) and that’s where my mistaken notion started!

If you have a printed Pictionary, please replace the canvas weave page and add the crepe weave one. A few more pages have also been added to the listing.

Happy weaving!

Please email comments and questions to