Dealing with Extra Heddles

Marcy Petrini

2/8/2016

I am going to thread a shawl across the entire width of my loom and I am quite sure that I have enough heddles on all of my shafts. So, I start threading and, sure enough, I do have enough – in fact, I have too many! On one side of my loom, I have lots of extra heddles. What can I do?

I cannot leave them at the edge of the shafts for two reasons: the first is that, especially if they are metal heddles, the weight on one side will be greater than the other, so the shaft will rise unevenly (in a counterbalance or countermarch loom, the balance will be off). This can cause a shuttle traveling down the race to catch threads and form errant floats because the shed is not open uniformly.

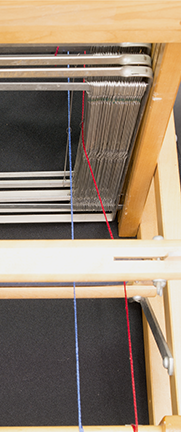

The second reason not to leave extra heddles on the side of the shafts is that the warp ends at the edge won’t travel the same distance as those in the middle, because the ones in the middle will be straight, the ones at the edge have to curve around the heddles – the more the heddles, the larger the curve. For example, as seen from above, look at the difference in the blue warp which has a straight path and the red warp which travels around the heddles. .

As the weaving progresses, a thread with the path like the red above will be sure to develop tension problems.

My only solution at this point is to take the extra heddles off the shafts, being careful to tie each bundle at the top and at the bottom before slipping them off the shaft, as shown below. This way, it will be easier to place the heddles back onto the shafts when they will invariably be needed later.

A much better solution is to plan ahead: disperse the extra empty heddles throughout the threading. This requires knowing the total number of heddles on each shaft, which is a very useful piece of information, regardless. Any time I add heddles, or move them, I make sure that I know how many heddles are on each shaft.

Since I know how many heddles my weaving will require, I can figure out how many blank heddles to leave when threading, as shown below. This has the advantage that, should I mis-thread, I have extra heddles if I need them in fixing my error. In this photo, two sets of threaded heddles flank a set of empty ones.

When the width of the weaving is less than that of the loom, extra heddles can be left at the edges, but there should be approximately the same number on each side on each shaft. To do this, I must know not only the total number of heddles on each shaft, but also the center, so I can figure out where I should begin threading by counting half the heddles from the middle; I still like to leave blank heddles as shown above, in case of an error.

More on Weaving Errors at Convergence®. For now, count those heddles!

Please email comments and questions to

Advancing Twills

Marcy Petrini

2/1/2016

A shawl woven in a 40-shaft advancing twill just came off my AVL loom. Here is a preliminary photo – a much better photo must wait until Terry can take it.

You can see the bands of warp (red-purple) and weft (blue-purple) interlacing. I love advancing twills and what I like about my 40-shaft loom are two major advantages: one is that a complicated treadling has to be entered once and then becomes automatic; yes, I must pay attention to avoid accidentally skipping a step which can be easily done and cumbersome to undo. But this particular twill is threaded as a straight draw 1 to 40 and has a treadling repeat of 239 steps. Clearly I wouldn’t be able to weave that easily without a computerized dobby.

The other advantage is that it forces me to design the structures from scratch, there is no reference – “green book” or “red book” – for 40-shaft structures. I must understand the structure pretty well to come up with the cloth I want.

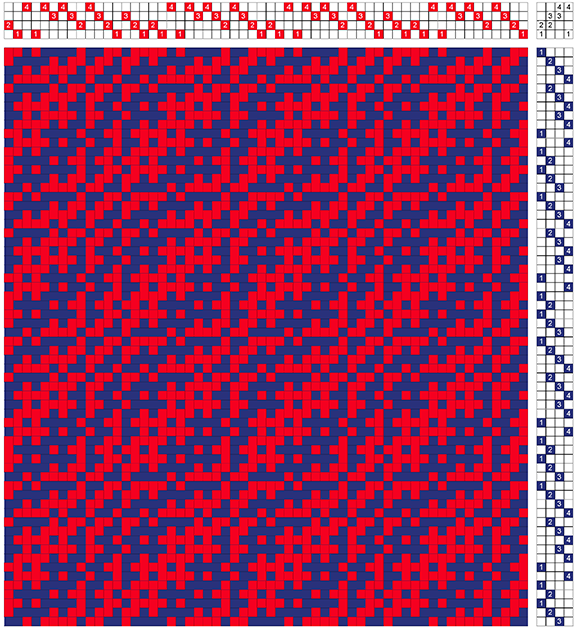

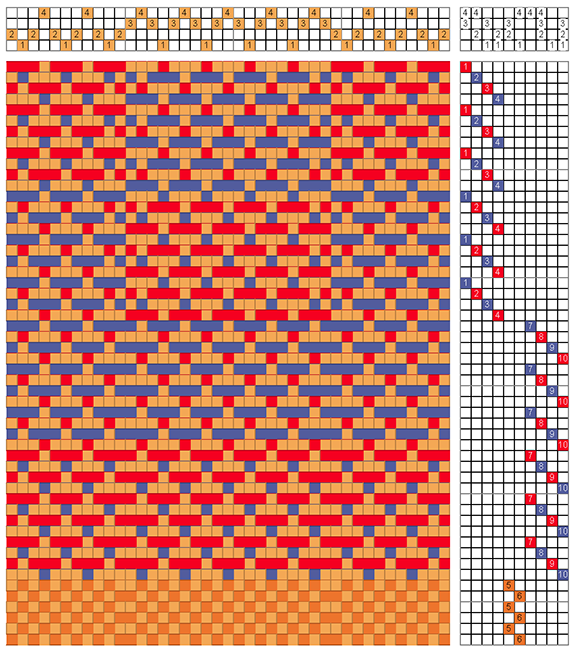

Advancing twills can be woven with many fewer shafts; on 4-shafts, the “advancing” generally occurs in the threading and, for a more complicated motif, the treadling. Here is the draft of an example (for a better view, try to left-click, or maybe right-click, the draft and open in a new window that will appear under the current tab):

From the threading and treadling we can see why it’s called an advancing twill: one shaft is deleted at the beginning and one shaft added at the end of a straight twill repeat to make the next repeat. Here there is a complete repeat of a straight twill to start the threading of the motif, but that’s not necessary. And other twills, like pointed, can serve as the starting point of the advancing twill.

Here is the fabric that corresponds to the draft:

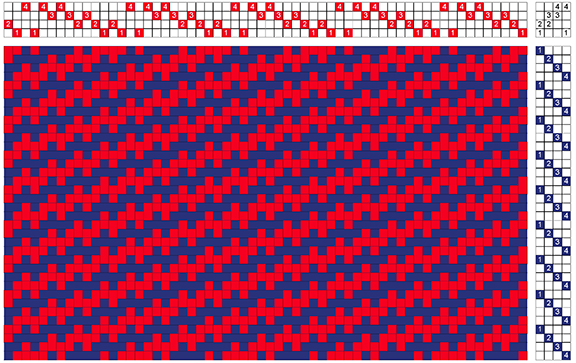

The treadling sequence for this advancing twill is 16 shots long, not too bad. We can simplify it by using a straight twill treadling, and that results in an interesting zig-zag motif down the fabric as shown in the draft below:

For an interesting twill “line”, try to advance a twill!

Please email comments and questions to

Double Binding Technique for Rag Rugs

Marcy Petrini

1/25/2016

In 2014, I was fortunate enough to visit the Casa das Tecedeiras (Weavers’ House) in Janeiro de Cima, one of the Schist Villages in the Serra da Estrela mountain range, in Central Portugal. While a lot of the traditional weaving is no longer done on a regular basis in the village, various rag rugs are pretty common in Portugal and those from Janeiro de Cima are typically woven using a double binding technique. At the Weavers’ House we saw several being woven and we learned about the technique. (I co-author an article in Shuttle Spindle & Dyepot about the fiber traditions of Portugal, Spring 2015, 36-40).

Once home, I set up a sampler to practice what I learned in preparation of writing the article. Since then I used the technique to weave a rug with fleece weft, and now I am returning to its tradition: I have a warp on the loom to weave a rag rug.

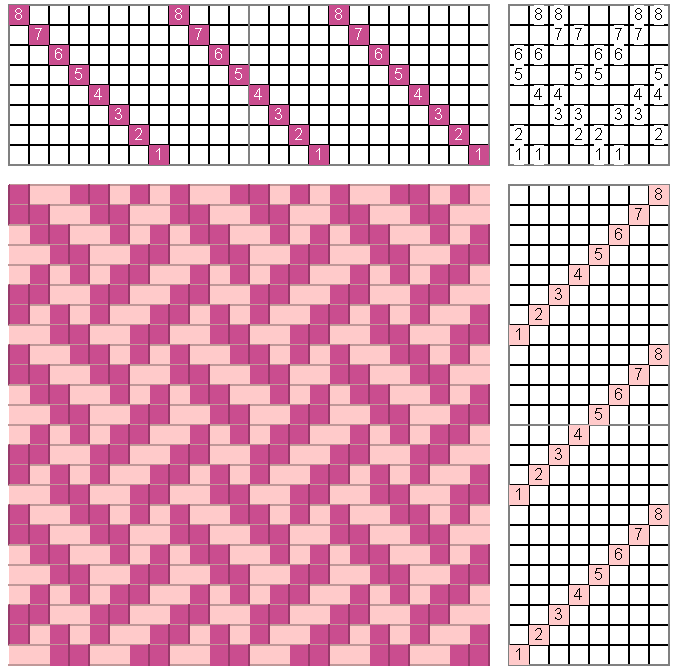

On four shafts, the threading has two blocks, each of which can be repeated as long as desired, since the floats are limited; three threads are used in the transition from one block to the other. In weaving, two wefts are used: on one side, one weft is shown in one block, the other in the second block. Underneath, the wefts are reversed. The sample below shows all the possibilities.

Starting from the top of the sample, there is a large blue block in the middle, which is red underneath. Similarly, the two red blocks on each side of the middle block are blue underneath. The block colors can be reversed, as shown in the second section, by reversing the order of the shuttles. It is also possible to weave a solid area of each color, as shown in the 3rd and 4th section. A small section of “pseudo plain weave” is woven with a thin weft at the beginning and ending of the rug to make a flexible hem. It’s “pseudo plain weave” because where the threading of the blocks change, the plain weave is interrupted by floats.

The draft that corresponds to the sections of the samplers is:(for a better view, try to left-click, or maybe right-click, the draft and open in a new window that will appear under the current tab):

The draft shows the structure, but in the cloth, one of the two wefts, red or blue, disappears underneath the other. In effect the rug is double thickness, which makes it sturdier than a plain weave rag rug, all other things being equal (same fiber strips, warp, etc.).

The draft shows two repeats of block B (2, 1, 2, 4) on each side and five repeats of block A in the middle (3, 4, 3, 1); when weaving, the blocks can be repeated as needed; my warp on the loom right now has the following repeats across a width of 36”: A 13, B 27, A 23, B 27, A 13. The transition between blocks A and B is threaded: 2, 1, 2 (incomplete block A) and the transition between blocks B and A is threaded: 3, 4, 3 (incomplete block B). Since I am starting with block A, my selvage at the start is: 2, 1 (half block A) and the selvage at the end is: 2, 1, 2, same as the transition from A to B. While in Portugal I noticed that they weavers were using 8-shaft looms, even though the technique only needs four shafts. When I was planning the treadling, I realized why: 10 treadles are needed to tie-up all the combinations and 4-shaft looms typically have six treadles.

However, by using two feet, I was able to weave all the combinations as follows:

| Treadle | Shafts |

| 1 | 1 |

| 2 | 2 |

| 3 | 3 |

| 4 | 4 |

| 5 | 3 & 4 |

| 6 | 1 & 3 |

Then I can treadle the blocks using these treadles:

| 5 |

| 2 & 4 together |

| 6 |

| 1 & 2 together |

The shuttles alternate and to reverse the color, the shuttles are switched, as shown in the drawdown. Similarly, to weave a solid color across, we treadle:

| 4 |

| 2 & 5 together |

| 1 |

| 2 & 6 together |

And we treadle the header with thin weft for the hem: treadles 2 & 3 together vs. treadles 1 & 4 together.

Next time you plan on weaving a rag rug, try this technique!

Please email comments and questions to

Plaited Twills

Marcy Petrini

1/18/2016

At the meeting of the Chimneyville Weavers and Spinners Guild this past Saturday, the topic of plaited twills came up when I showed an example of the blog with the plaited twill Christmas fabric from 14-Dec-16.

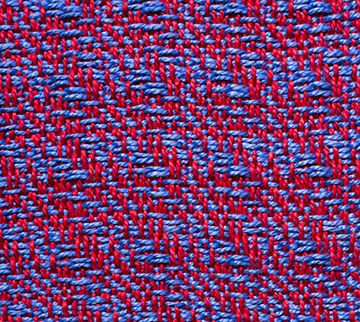

I love plaited twills and I had woven that Christmas fabric a long time ago. More recently, I wove a shawl in a 10-shaft plaited twill. Here is the shawl, a close up of the fabric and its draft (for a better view, try to left-click, or maybe right-click, the draft and open in a new window that will appear under the current tab):

From the fabric close up and the draft, we can see why it’s called a plaited twill: each “ribbon” of left-handed twill seems to disappear under a “ribbon” of right handed twill – and vice versa – as when we braid real ribbon. The size of the “ribbons” in the plaited twill can depend on the number of shafts available.

There are two ways to approach plaited twill. One, not surprisingly as a twill; the other as a double two-tie unit.

Below is the draft of an 8 shafts plaited twills, using pattern # 358 from Carol Strickler’s A Weaver’s Book of 8-Shaft Patterns. It is threaded as a straight twill and all of the plaiting occurs in the tie-up.

The other way to weave a plaited twill is to use a threading based on a double two-tie unit weave (think summer-and-winter), shown below. The nomenclature comes from the threading. There are two shafts, 1 and 2, which serve as tie-down threads, hence the name two-tie. If we look at a repeat of the structure, shafts 3 through 8 are the pattern shafts and they alternate with a tie-down shaft; if we think of each repeat as a block, the name double comes from the fact that both tie-down shafts are used in the block. This draft is from pattern #355 from the same book. Here the plaiting occurs as a combination of the tie-up and the treadling. Explore Carol's book for many, many options on 8 shafts.

In general, using a double two-tie unit for plaited twills is more versatile than using a twill threading because we re-use two shafts. However, the treadling can be more complicated; we can see from above that two treadles alternate throughout the treadling: one has all of the shafts plus tie-down shaft 1 and the other has all of the shafts plus tie-down shaft 2.

There is another option for all of these twills. The draft above shows the threading to be ascending from shaft 3 to 8. The plaited twill from my shawl also uses a double two-tie unit but after ascending, it reverses, forming a point.

Can plaited twills be woven on 4 shafts using either one of these two methods? No; we can determine the reason if we examine the actual drawdowns. What makes the plaiting is a combination of left-hand and right-hand twills; on four, we don’t have enough shafts to have two twills intersecting when threaded as a straight draw or as a two-tie unit.

However, we can weave a twill on 4 shafts that has right and left-hand twills, the beginning of plaiting. Below is a draft of a three-thread herringbone from Marguerite Porter Davison’s A Handweaver’s Pattern Book:

There are other treadling variations on this threading in Davison's book, so the possibilities abound.

Please email comments and questions to

Roc Day

Marcy Petrini

1/11/2016

Roc Day is the gathering of spinners that occurs the day following Epiphany. The legend has it that after fortnight, women, who had put up their wheels and looms for the holiday baking and chores, returned to weaving and spinning, but the men wouldn’t return to their farm duties until the following Monday. In between this time, the men would harass the women (figures, nothing has changed), so the women wouldn’t get much done, but merrymaking resulted. Roc is derived from old German and Scandinavian words for the distaff, especially when holding wool or flax.

I am not sure about the merrymaking or the men returning to farm duties in the middle of winter, but when I was growing up in Rome, Italy, the holiday season did end on Epiphany and normal life resumed on January 7th.

Technically, then, Roc Day is January 7th, also known as Saint Distaff’s Day. However, we celebrate the Gulf Coast States Roc Day on the 1st Saturday after the New Year holiday. Our “reason” for the get-together is to spin, knit, or use some other portable fiber technique, but we visit, invite vendors so we can shop, show off our work, catch up on the year events, and have a leisurely lunch with old and new friends. Fiber guilds in the region rotate hosting Roc Day. I am just back from Roc Day 2016, a wonderful event hosted by the Bayou Yarn Benders of Baton Rouge, LA. In addition to the visiting, shopping and, well, yes, eating, I was a vendor, providing the manuscript that my husband Terry Dwyer and I produce.

Here are some people at Roc Day 2016 having some serious fiber fun!

Please email comments and questions to