Planning and Evaluating a Project: II

Marcy Petrini

2/29/2016

Did you think about why you practice the crafts you do (as I discussed last week)?

Once you are clear on the reasons why you practice your crafts and on why you did a particular project, it’s time to proceed with the work and then evaluate it. Barry Bonds, the noted baseball player turned coach, recently talked about helping young players evaluate themselves and he said: “If you want self-evaluation, well, don’t be afraid of the truth.”

Nicely put; we do have to be honest in evaluating ourselves, but this is not the time to chastise yourself! That’s why the Evaluating a Project form has the question: “what is good about this piece?” right after you rate your overall satisfaction with:

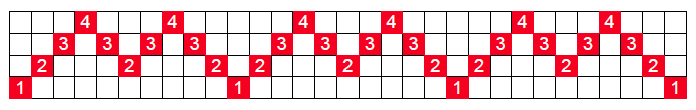

![]()

These mean: “this project is a winner”, “I am happy”, “it’s OK”, “I am not happy”, “Kill this project”. Truly, it is seldom that a project really falls into the last category, but even if it did, there usually is something good about it, or at least a valuable lesson to learn.

Next, you should think about what you would do differently if you were to redo this project, and how the piece compares to what you expected it to be (more on this later). The specific items listed on the form should also be assessed. There may be others, but those are the most important.

From my many years of weaving and of teaching, I have concluded that there are five major reasons why our project don’t get a trophy or at least a happy face. These are primarily for weaving, but apply to other fiber crafts as well.

First, it’s craftsmanship; we make physical errors because we are unfocused, distracted, in a hurry, or tired; or we don’t think about, or maybe we don’t understand, the process and its limitations. Take time, both before the project to understand what you are about to do, and while doing; work by hand is slow, don’t rush it.

The second is that there is a mismatch between the item produced and the materials or techniques used; I have seen a “cardboard” sweater; an overshot skirt that looked like a blanket; a scarf the weight of a table runner; and placemats woven with wool. My most egregious error was in the early 80s. I had woven a wool ruana while I lived in a cold climate; I loved it, but I had moved to Mississippi, which has a much milder climate, so I thought a less cozy ruana would be more practical. In weaving a new one, I used the same yarn grist, sett, and pattern, substituting cotton and rayon for the wool. While the old wool ruana was light and fluffy – and warm – the new ruana was an armor! For the same yarn grist, the cotton is much denser and thus heavier; I should have used a much smaller yarn. Lesson learned. I moved on.

We already talked about unstated expectations last week. If you are transparent with yourself, you will be more likely to fulfill your expectations, no matter how lofty. But you are not likely to achieve expectations you didn’t set out to accomplish.

We talked about scale last week. You don’t need drawdown software to think about scale. Simple arithmetic can do the trick. For example, look at the threading of three repeats of the following twill:

One repeat is 10 threads long. If you were to sett the warp at 10 ends per inch (epi), the pattern would be 1” wide; you probably “knew” that, without consciously working through the simple arithmetic: 10 threads divided by 10 ends per inch equals 1”. Similarly, at a sett of 20 epi, the pattern will be ½”, just a simple 10/20 = 0.5”. Granted, most pattern repeats and setts don’t come out that even, but still, they are simple. A pointed twill has a repeat of 6 threads; for a yarn sett at 20 epi, the repeat will be about 1/3" wide. Most of us are visual people, though. Just grab a ruler and look at what 1/3" looks like; or draw it by hand on a piece of paper.

This brings us to the last reason why our project doesn’t meet our expectations: we didn’t visualize the end product. This one is unfair. It takes years of experience to look at a yarn, do a drawdown of the pattern, think about scale, love the colors and visualize what all of it together will look like, if you haven’t used all of those factors together before. I don’t think of this reason as a failure of the project, although I have heard this often as a complaint by people: “but it doesn’t look like the way I thought it would.” Get over it. If all of the design considerations and the craftsmanship are good, than the project is good. Try to figure out what the difference is between what you envisioned and the end product. It’s the only way to learn.

Possible reasons are the color interactions in weaving, especially if you looked at the yarns in a light that didn’t reveal the true color. A color may “pop” when you wanted it to blend, or it blends when you wanted it to pop. And pattern matters. Look at the figure below. Same colors in three color gamps, woven in plain weave, pointed twill and huck. The colors appear differently from being maximally blended in the plain weave vs. the floats of the huck.

Yarn may obscure the pattern. Yarn texture or variegation are the most obvious, but the distortion of warp and weft within the cloth can also be important. Look at the pointed twill drawdown on the left below; you can see blue crosses formed by 5 shots of weft with a warp dot in the middle. In the fabric on the right, woven with the same twill, the motifs become almost round because the top and bottom of the cross disappear with the fat, lofty warp pulling in. If I was set on wanting crosses, I could be disappointed. But it would be better to be happy with the blue-purple motifs in my cloth and learn why the crosses didn’t appear clearly.

It does take experience to visualize correctly, but it takes analysis as well.

Please email comments and questions to